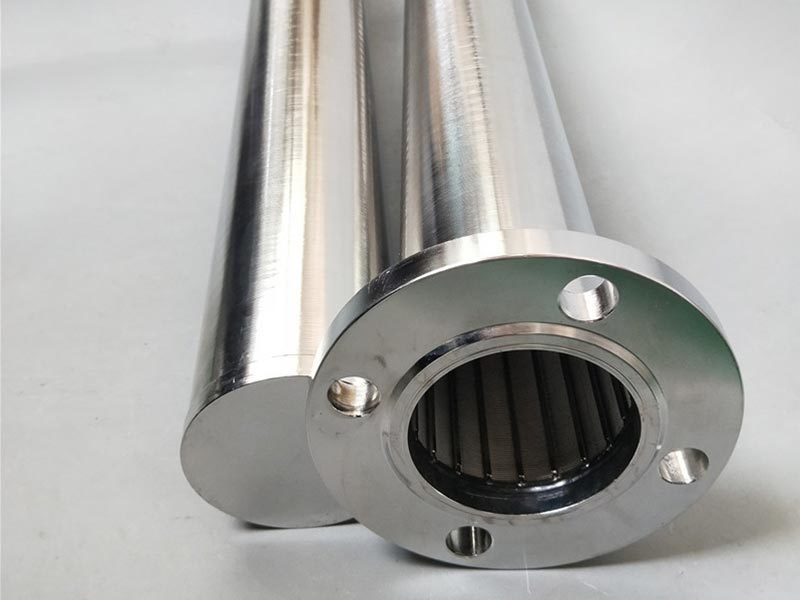

Nozzle distribution disk

The distributing tray is to make the oil and gas entering the reactor distribute evenly, improve the flow condition of the material flow, realize good contact with the catalyst and ensure the reaction effect

- Commodity name: Nozzle distribution disk

- Product Description

-

The distributing tray is to make the oil and gas entering the reactor distribute evenly, improve the flow condition of the material flow, realize good contact with the catalyst and ensure the reaction effect

The top dispensing tray consists of a tray plate and distributors uniformly distributed on the tray The purpose of the top dispensing plate above the catalyst bed is to uniformly distribute the reaction medium, improve its flow condition, and achieve good contact with the catalyst so as to achieve uniform distribution in radial and axial directions There are many kinds of distributors. Most of the hydrogenation reactors designed and manufactured in China adopt bubble cap distributors

In order to better break the liquid entering the downcomer into droplets and change the flow direction of the liquid from vertical to oblique downward to cause further diffusion, a breaker can be added under the bubble cap

Company Introduction:

The company places great emphasis on technological innovation, and its products are widely used in refining and petrochemical industries as well as nuclear power equipment. Currently, the company has supplied over 500 sets of supporting equipment, which are deployed in nearly 3,000 units of machinery.

The company boasts a well-established organizational structure, comprising four major departments—Marketing, Internal Operations, Chief Engineer, and General Office—which in turn include 14 specialized divisions such as the Customer Service Department, Sales Department, Technical Department, Project Management Department, Materials Department, Quality Inspection Division, Financial Management Department, and Administration & Human Resources Department. The company operates in a five-story office building and has four production workshops, providing customers with comprehensive services that cover design, manufacturing, and on-site support.

|

|

The company has established standardized management practices for production and office environments, maintaining a high-quality environment and a distinctive corporate culture. In September 2007, the company obtained certification under the “ISO9000 Quality Management System.” It has consistently implemented and passed annual audits with excellent results. The company has formulated a quality policy and objectives centered on “customer focus, high quality and efficiency, and continuous improvement; ensuring product quality, complying with laws and regulations, and providing dedicated service.”

Partner companies:

|

|

|

|

|

|

-

Key words:

- Nozzle distribution disk

Get a quote

Note: Please leave your mobile phone number, our professionals will contact you as soon as possible!

Related Products