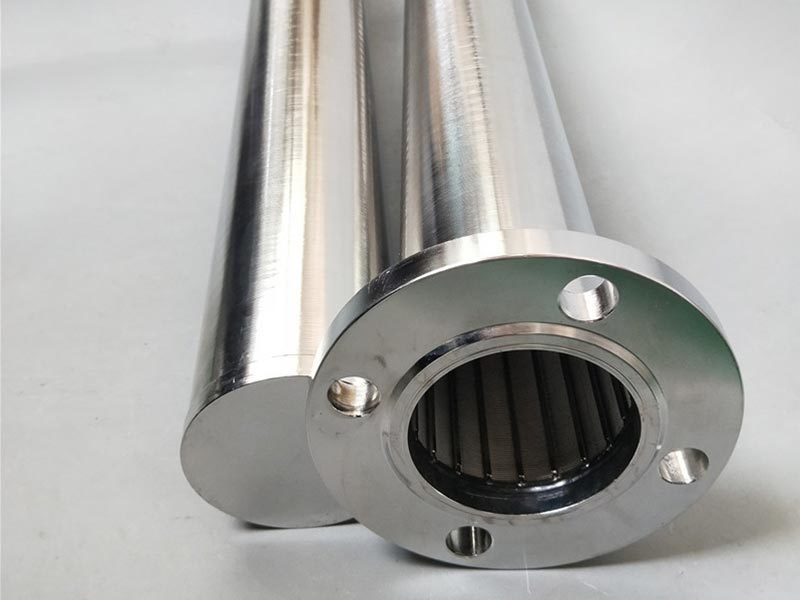

Screen demister

Wire mesh demister is a gas-liquid separation device. Gas can remove entrained mist through the wire pad of demister

- Commodity name: Screen demister

- Product Description

-

Product structure:

Wire mesh demister is mainly composed of wire mesh block and supporting device for fixing wire mesh block. Wire mesh is air-liquid filter screen made of various materials. Air-liquid filter screen is composed of metal wire or non-metal wire The non-metallic wire of the gas-liquid filter screen is twisted from multiple non-metallic fibers and can also be a single non-metallic wire The mesh demister can not only filter the larger liquid foam suspended in the airflow, but also filter the smaller and tiny liquid foam. It is widely used in gas-liquid separation devices in chemical industry, petroleum tower, manufacturing pressure vessel and other industries

Wire mesh demister (demister) is used to separate droplets entrained by gas in the tower to ensure mass transfer efficiency, reduce valuable material loss and improve the operation of compressor behind the tower. Generally, wire mesh demister is set at the top of the tower 3-5um droplets can be effectively removed. If demister is installed between trays, it can not only ensure the mass transfer efficiency of trays, but also reduce the distance between trays Therefore, the screen demister is mainly used for gas-liquid separation It can also be used as an air filter for gas separation In addition, the wire mesh can also be used as a buffer for various instruments in the instrument industry to prevent electronic shielding devices such as radio wave interference Now it has been widely used in environmental protection industrial production of chemical industry, petroleum, sulfuric acid medicine, light industry, metallurgical machinery

How it works:

When the gas with mist rises through the mesh at a certain speed, the mist collides with the mesh filament and is attached to the filament surface due to the inertia of mist rising Diffusion of mist on the surface of filament the gravity settlement of mist makes mist form large droplets and flow along the filament to the junction of two filaments Wettability of filaments the surface tension of liquid and the capillary action of filaments make the droplets larger and larger until the droplets gather so large that the gravity generated by them exceeds the combined force of the lifting force of gas and the surface tension of liquid that the droplets separate and fall from the filaments After passing through the mesh demister, the gas basically contains no mist Separate the mist in the gas to improve the operating conditions, optimize the process index, reduce the corrosion of equipment, prolong the service life of equipment, increase the treatment capacity, recover valuable materials, protect the environment and reduce air pollution, etc. Simple structure, small volume, high defoaming efficiency, small resistance, light weight, easy installation, operation and maintenance. The net defoamer has a collection efficiency of 98%-99.8% for mist whose particle size is ≥ 3 ~ 5um, but the pressure drop of gas passing through the defoamer is very small, only 250-500Pa, which is beneficial to improve the production efficiency of the equipment

Company Introduction:

The company places great emphasis on technological innovation, and its products are widely used in refining and petrochemical industries as well as nuclear power equipment. Currently, the company has supplied over 500 sets of supporting equipment, which are deployed in nearly 3,000 units of machinery.

The company boasts a well-established organizational structure, comprising four major departments—Marketing, Internal Operations, Chief Engineer, and General Office—which in turn include 14 specialized divisions such as the Customer Service Department, Sales Department, Technical Department, Project Management Department, Materials Department, Quality Inspection Division, Financial Management Department, and Administration & Human Resources Department. The company operates in a five-story office building and has four production workshops, providing customers with comprehensive services that cover design, manufacturing, and on-site support.

|

|

The company has established standardized management practices for production and office environments, maintaining a high-quality environment and a distinctive corporate culture. In September 2007, the company obtained certification under the “ISO9000 Quality Management System.” It has consistently implemented and passed annual audits with excellent results. The company has formulated a quality policy and objectives centered on “customer focus, high quality and efficiency, and continuous improvement; ensuring product quality, complying with laws and regulations, and providing dedicated service.”

Partner companies:

|

|

|

|

|

|

-

Key words:

- Screen demister

Get a quote

Note: Please leave your mobile phone number, our professionals will contact you as soon as possible!

Related Products